When we look to sustainable materials, concrete isn't always the first substance that comes to mind. In our blog, below, we discuss the surprising ways in which concrete will work harder than ever to become one of our most sustainable materials across construction and interiors.

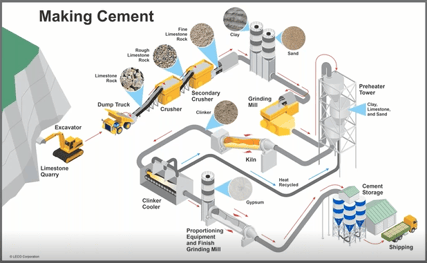

Concrete is one of the most widely used building materials in the world, and for good reason. It's strong and durable. However, the production of traditional concrete has a significant environmental impact due to the large amount of energy and resources required to make it. In recent years, there has been a growing focus on the sustainability of concrete, leading to the development of new technologies and materials that are more environmentally friendly. One of these materials is GFRC, which is becoming increasingly popular in the construction industry.

GFRC is a type of concrete that is reinforced with glass fibres instead of steel. This results in a material that is lighter, stronger, and more flexible than traditional concrete. Additionally, because GFRC is made with less Portland cement, which is a major contributor to the carbon emissions associated with concrete production, it has a lower carbon footprint. GFRC is also highly resistant to corrosion, which makes it a great choice for buildings in coastal areas or other environments with high levels of salt in the air.

There have been several changes in the production of GFRC that have made it more environmentally friendly compared to traditional concrete. Here are a few examples:

- Reduced use of Portland cement: Portland cement is a major component of traditional concrete, and its production is responsible for a significant amount of carbon emissions. In GFRC, the amount of Portland cement used is typically reduced by up to 50%, which significantly lowers its carbon footprint.

- Use of recycled materials: Our GFRC manufacturer, and many others, use recycled materials in their production process, such as recycled glass fibres and post-consumer waste, to reduce the amount of waste that goes into landfills.

- Lower energy consumption: The production process for GFRC requires less energy than that of traditional concrete, mainly because GFRC is lighter in weight and requires less transport energy.

- Longer lifespan: GFRC is highly resistant to weathering, corrosion, and other environmental factors, which means that structures built with GFRC can have a longer lifespan than those made with traditional concrete. This means that GFRC structures do not need to be replaced as frequently, reducing the amount of waste generated over the long term.

- Reduced transportation impact: GFRC is lighter than traditional concrete, which means that it requires less fuel to transport it to construction sites. This results in a lower carbon footprint from transportation.

Another way to reduce the environmental impact of concrete is by using EF technology. EF technology is a process that reduces the amount of cement needed in concrete production. Cement production is responsible for a significant amount of greenhouse gas emissions, so reducing the amount of cement used in concrete production can significantly reduce the carbon footprint of the material. EF technology achieves this by using chemical additives that improve the workability and strength of the concrete, allowing for less cement to be used.

Overall, these changes in the production process of GFRC have made it a more sustainable option. As the demand for environmentally friendly building materials continues to grow, it is likely that GFRC will become an increasingly popular choice for architects, engineers, and builders looking to reduce the environmental impact of their projects.

Another advantage of GFRC is that it can be moulded into virtually any shape or size, making it a versatile material for architectural design. It can be used to create complex shapes, intricate patterns, and even textured surfaces that mimic natural materials like stone or wood. This makes it a popular choice for cladding, facades, and decorative elements in both commercial and residential buildings.

Looking to the future, it seems likely that GFRC will continue to grow in popularity as more architects, engineers, and builders become aware of its advantages. As the environmental impact of construction becomes an increasingly important consideration, GFRC's lower carbon footprint and other sustainable features will make it an attractive choice for many projects. Additionally, advances in technology and production methods may make GFRC more cost-effective and easier to work with, further increasing its appeal.

Overall, GFRC represents a promising evolution in the sustainability of concrete. While it may not be the perfect solution for every project, its combination of strength, durability, and sustainability make it an increasingly popular choice for a wide range of applications. As the construction industry continues to evolve and adapt to changing environmental concerns, GFRC is likely to play an important role in shaping the buildings of the future.

https://info.leco.com/blog/clinker-concerns-a-metallographic-analysis-of-cement

The original methodology of cement production

https://bellona.org/news/industry/2022-02-circularity-in-cement-and-concrete

Improvements showing the recycling of aggregates